Amorelie contributed to normalise the narrative around sex-toys by focusing on slick design products.

This industrial design niche is still being explored with many opportunities for innovation.

Sexual intimacy tool

Sex, as much as self-love, needs the right frame of mind. I became intrigued by developing objects that could be used to create intimacy without being explicitly sexual (at that time, Amorelie was exploring new typology of products, such as perfumes and cosmetics).

There were some products already on the market, like Love Is Art, a poetic concept with the potential of visualising the beauty of love.

Hello Touch (by Jimmyjane) was also a very interesting product, because it tried to link the pleasure given by a vibration with the one given by a massage. Unfortunately, it seems that Hello Touch was not delivering what it promised. It was bothersome to wear. Also, it looked too techy with all those wires and strips and it was later discontinued.

With the exception of Wand neck massagers, which are notoriously known to be external vibrators in disguise, I couldn’t think ab out any other massage device combined with a vibration. It felt it was an opportunity to explore a new direction.

My approach was to identify an existing gesture first, then to explore how it could have been eased or amplified by a tool.

Deep Tissue Massage

I started researching tools and the techniques currently used in bodyworks and massages. Among them, the elbow pressure was particularly interesting as it enables to direct intense pressure when massaging more fibrous tissues in order to melt away muscle tension.

Concept

I envisioned a wearable massage device that would enable the user to provide elbow pressure with their hands.

To do so, I would have needed to virtually ‘move’ the elbow under the palm of the hand, so that the same kind of pressure can be provided by pushing the hand itself into the body.

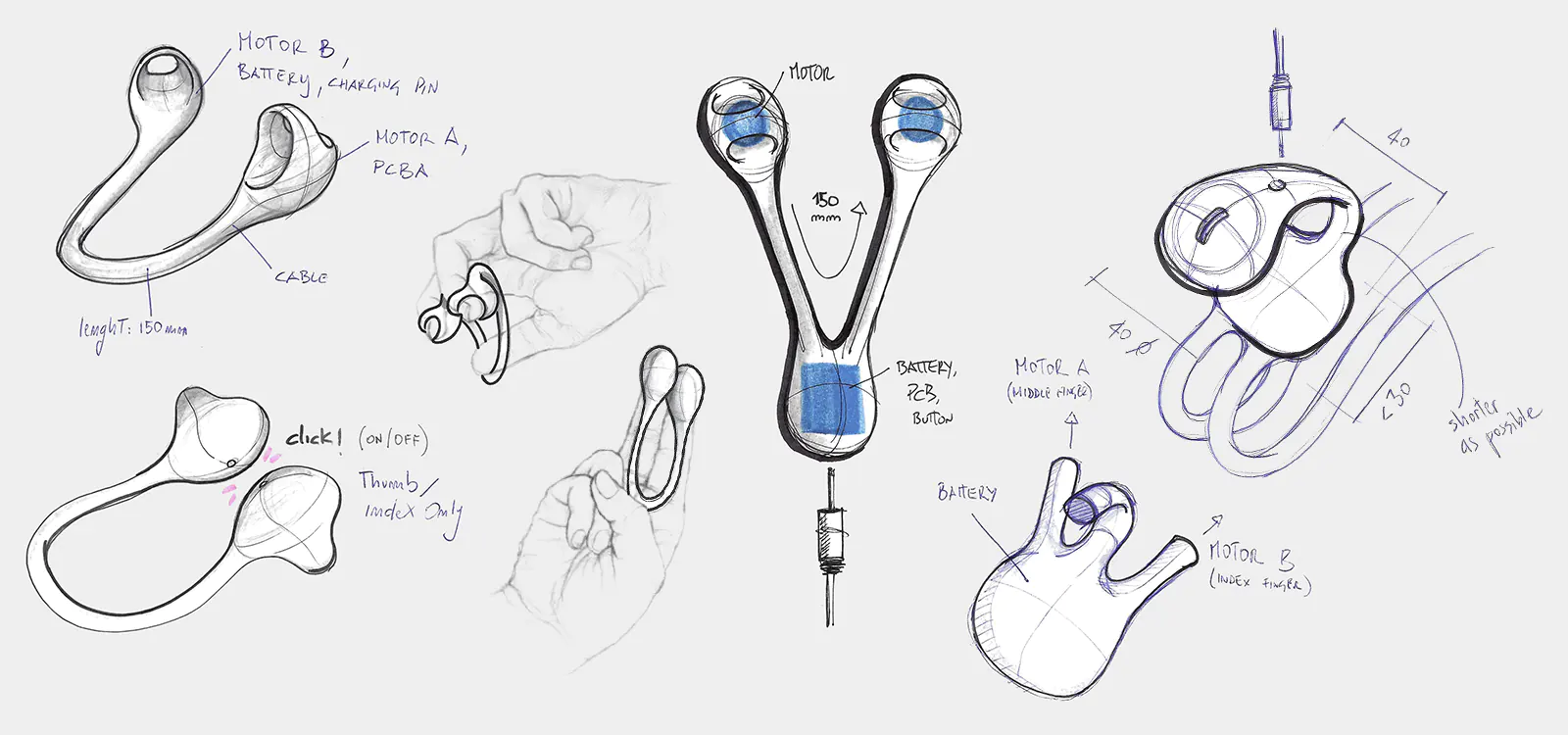

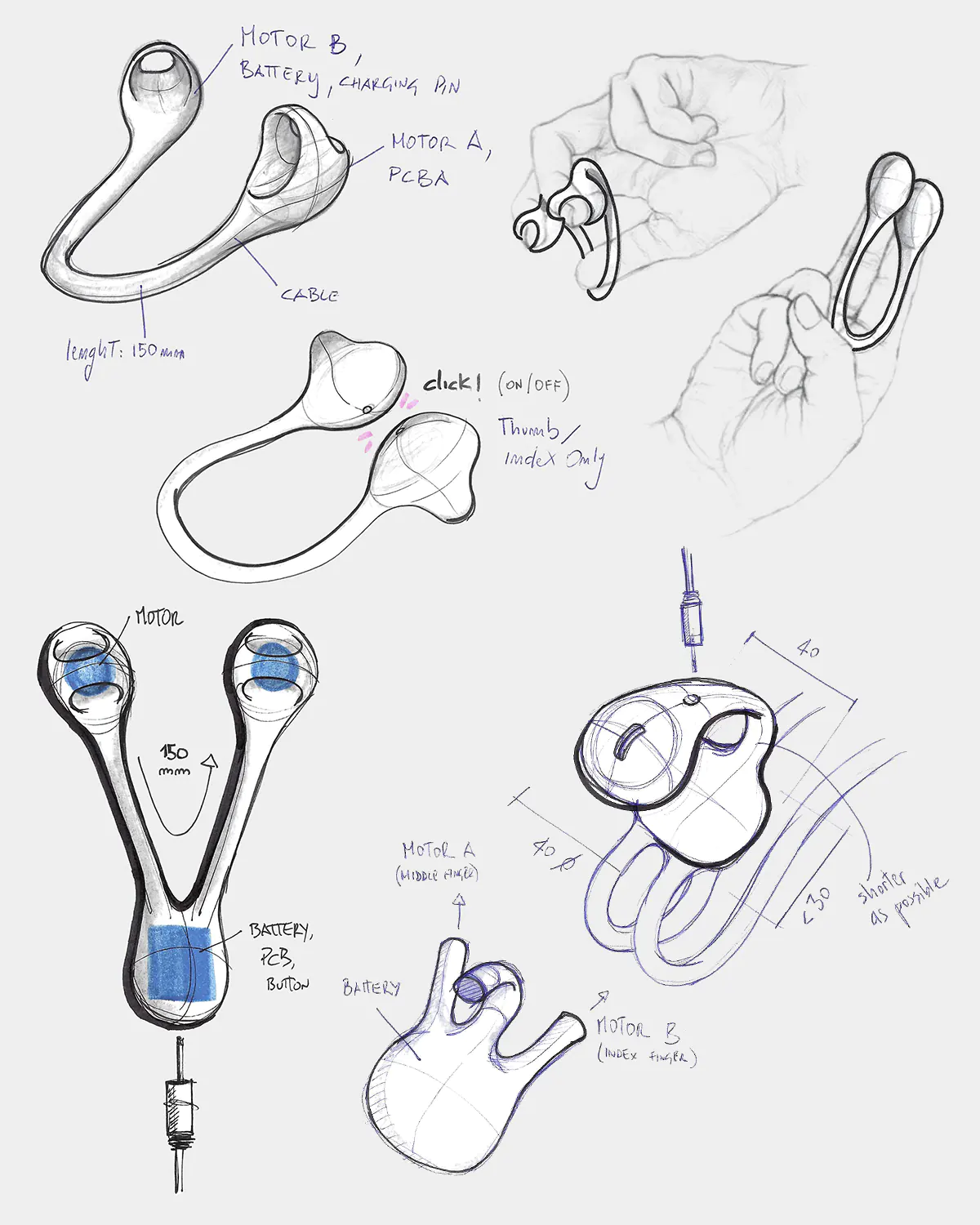

Sketches

There are a number of components that always need to be fitted in a vibrating device: motor, battery, charging module and PCBA. Already while sketching, I would need to remember to leave just enough room for them.

I took inspiration from the Hello Touch and tried to develop it further by creating a device that could feel more user-friendly and softer. The battery would have been located under the palm. While thinking about how to make it wearable, I suddenly realised how much more sense made to shift the vibration from the fingers to the palm itself.

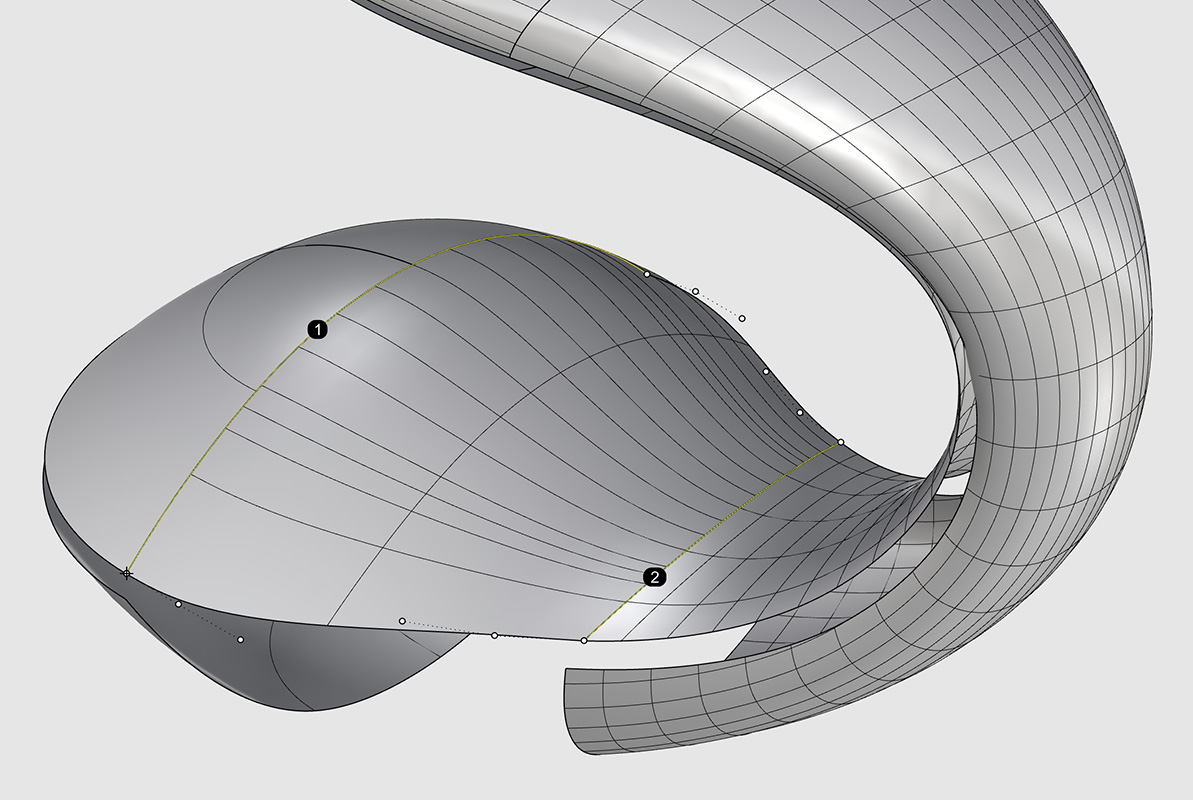

Development

I used CNC rapid-prototyping techniques to test different ways of wearing the device. The first prototype (the one in light blue in the image below), was pivoting on the skin when pressed against the body. After a number of iterations, I finally switched from an elastic band to a ‘clip’ solution.

Anthropometrics

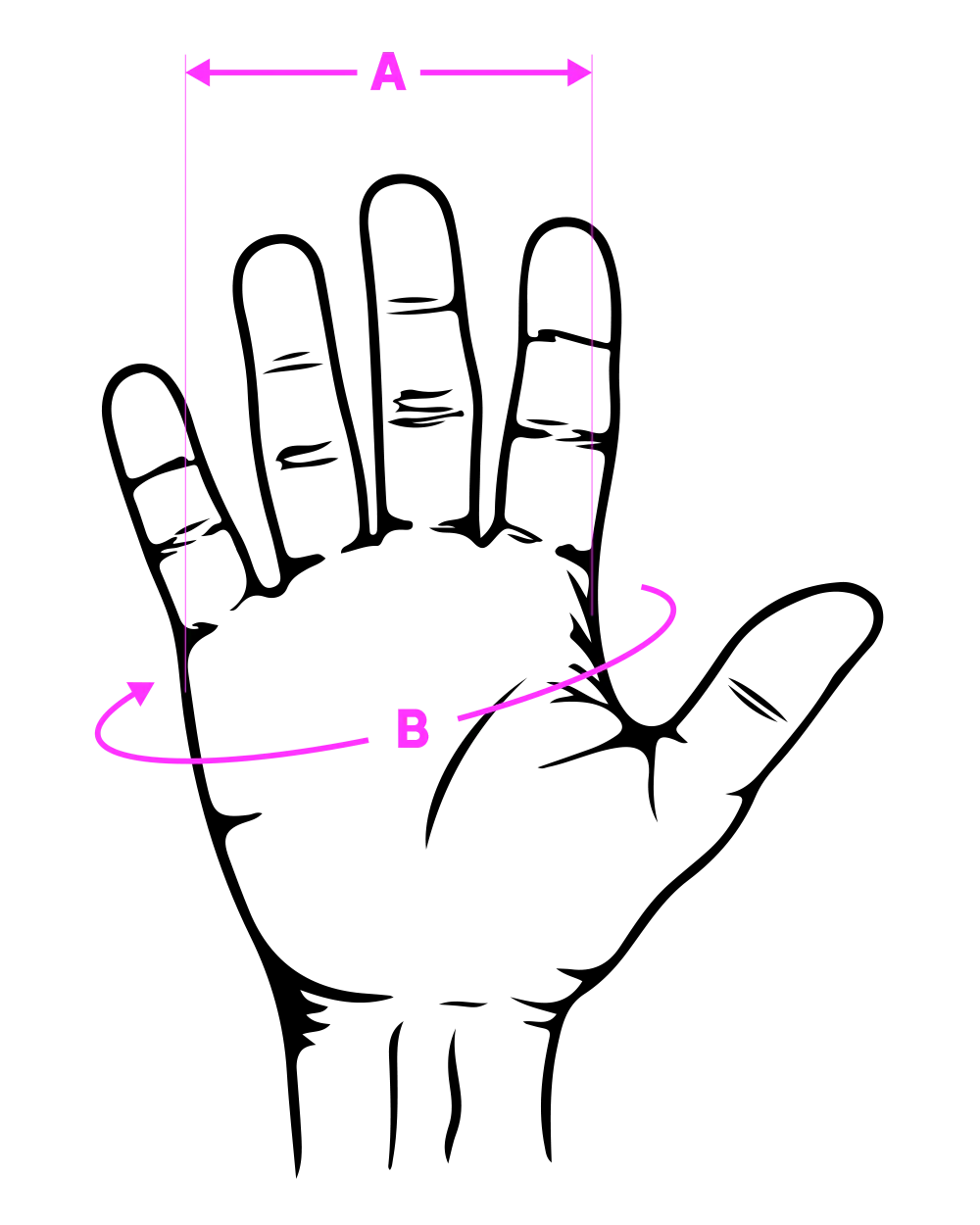

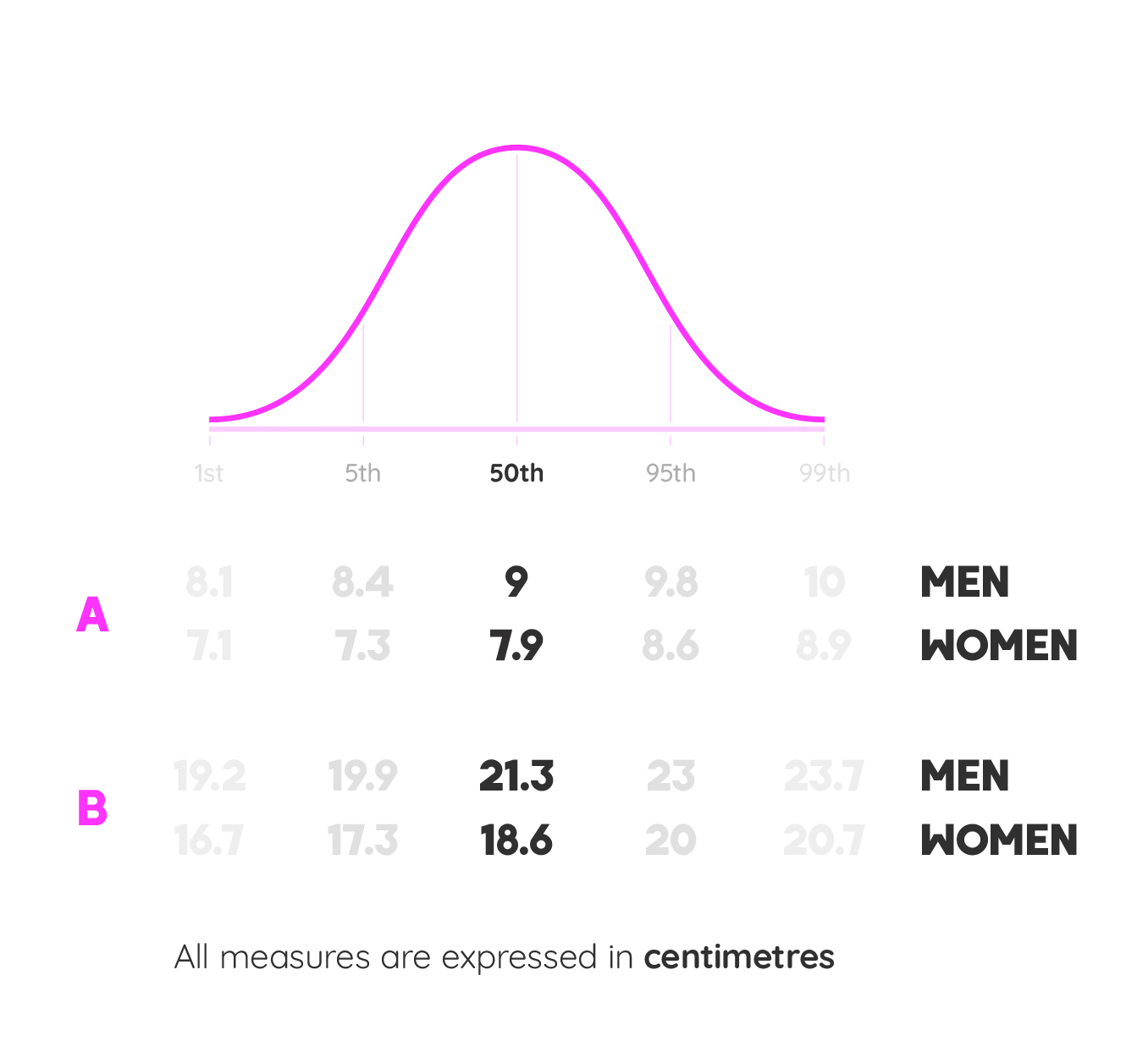

Once I narrowed it down the shape, I researched whenever we had to produce the device in different sizes.

Luckily, because of the position where the device clips on hands, there isn’t much difference from a small to a big hand size and I could define the device’s dimension as a one-fit-all solution.

Finally, the dimensions of the massager were then defined according to the percentile average hand width (A) and circumference (B) of the European population.

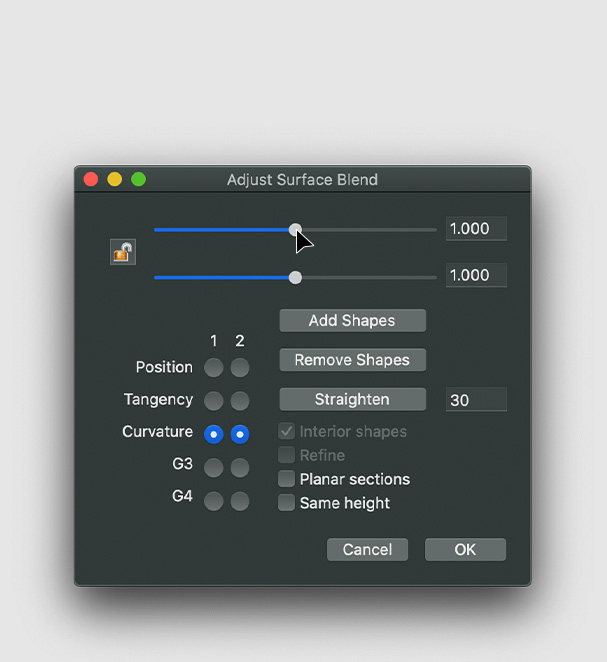

The shape went through a number of refinements until both ergonomics and aesthetics requirements were met.

Every iteration of the shape has been 3d-modelled, printed on a CNC-machine and tested.

Engineering

Once I learned about the optimal dimensions, I had to adjust the shape to fit all the components inside. These are standardised parts, making it possible to rather decide for a stronger motor/vibration or a more durable battery/run-time by picking bigger or smaller components.

The manufacturer shared a draft of a mechanical solution together with a quotation for production and unit costs. This information allows to determine the viability of the toy in its brand and for the targeted customer’s group.

Vibration Patterns

The PCBA is programmed to vibrate with a certain rhythm and intensity. Many sex-toys have up to 10 vibrating patterns, though users generally prefer constant vibrations. Therefore, I opted for the three steps of intensity and only one variable patterns for more creative use.

User Testing

Once we received a working prototype I could conduct proper testing and make further refinements.

Final Product

For reasons that go beyond the product itself, the massager was not put into production. I would have loved to see this one being sold and learned about the opinion of the customers, but hey, on the other hand I can share its development. 🙂